The Production System

In Sweden, we have been producing approximately 2 TWh of biogas per year for many years from sewage treatment plants, co-digestion facilities, and industrial plants. The expected significant growth is primarily anticipated to occur from larger co-digestion facilities and, to some extent, farm facilities, while sewage treatment plants and industrial facilities are expected to grow slowly. Now there is a proposal for a national target of 7 TWh per year from anaerobic digestion by 2030, with a long list of projects under construction. Many of these projects are based on the digestion of manure along with other agricultural by-products and residues. To become truly efficient, these facilities also need other substrates such as household food waste and food supply chain by-products. Biogas plants also have a potentially significant role to play in the redistribution of plant nutrients, which are often in excess in some areas while scarce in others.

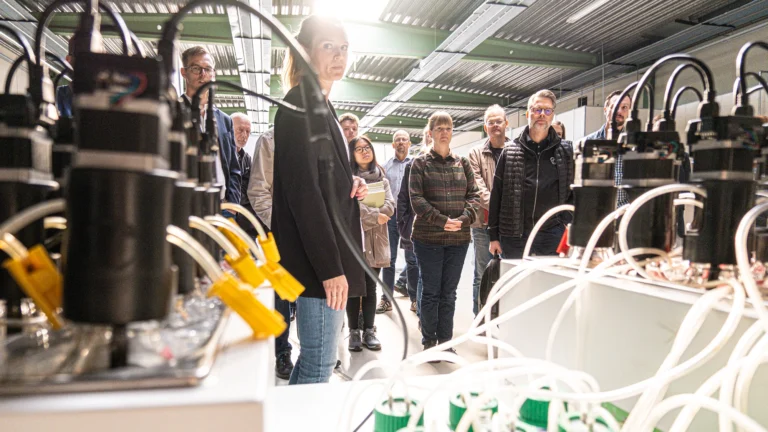

The development primarily points towards larger, more standardized, and industrialized biogas plants. Consequently, localization and logistics become crucial aspects of a sustainable production system. Much of the additional production will take place in rural areas where there is ample manure and demand for the digested biofertilizer. Gas will increasingly be liquefied or injected into the gas grid to reduce dependency solely on local demand. Infrastructure for transporting raw gas from multiple digestion facilities to centralized upgrading and liquefaction of biogas could be a solution to reduce the extensive transports occurring around a biogas plant. Alongside this development, the number of farm-based facilities producing electricity and heat while utilizing their plant nutrients is also growing. These can be a viable alternative where it's not feasible to establish larger facilities.

To further increase biogas production in the future, land use in agriculture needs to be intensified sustainably. There are ample opportunities to produce much more biomass than today, for example, through increased intercropping and fodder grass, cultivation. What is harvested from the forage can also be fractionated, divided into a more concentrated protein part for fodder while the remainder serves as excellent biogas substrate. In this way, together with the cultivation of cover crops and more, the farming system can simultaneously become more sustainable and contribute to a significantly increased biogas production.